Busbar Design Basics for System Success

5 Considerations to Note Before Entering into the Busbar Design Phase

When it comes to busbar design basics, there are 5 considerations you should take into account to help aid in system success.

Below, the bus bar manufacturers here at EMS have highlighted the most important factors to consider before entering the busbar design phase.

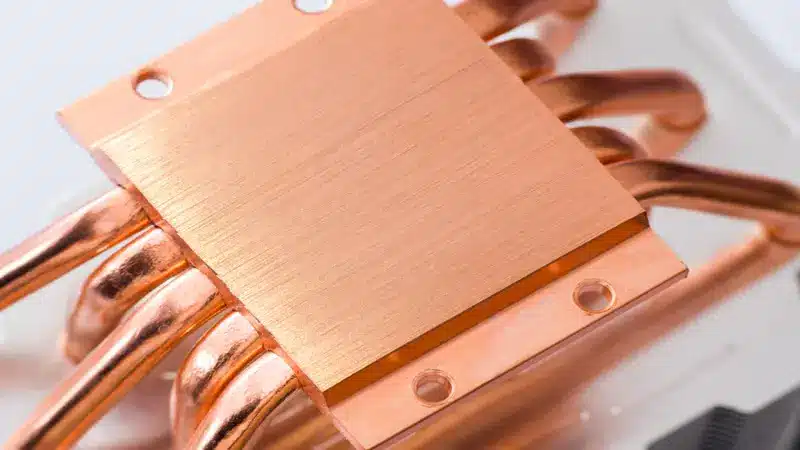

Busbar Material

In most cases copper will be the preferred busbar material, but there are some advantages to selecting aluminum. You can find helpful comparisons between these materials in our Aluminum Busbar vs Copper article.

Conductor Material & Dimensions

Selecting the proper conductor material is also essential for achieving the necessary electrical performance and mechanical requirements. Material options typically include copper, aluminum and various other copper alloys.

The mechanical dimensions of the conductor, including minimum width and thickness, is determined by the material selected, the mechanical requirements and the current-carrying requirements. Conductor thickness may be modified if there is a selection of tabs or terminations where studs, nuts or threaded inserts are needed.

The ground return conductor must be equal in size and circular mil area to its corresponding voltage conductor.

If minimum inductance is a busbar design requirement, you may want to consider minimizing the thickness and maximizing the width of the conductor.

Busbar Plating

Busbar plating is necessary for many applications in order to protect against corrosion and provide good contact surface, maintaining low resistant contact when attached.

EMS provides busbar plating in silver, nickel and tin.

Busbar Epoxy Coating

Busbar epoxy coating is necessary to protect against electrical shock, corrosion, high voltage arcing and current-induced magnetic fields. It is also used to improve conductivity.

Busbar epoxy coating is necessary within various industries particularly where harsh environment conditions exist, such as at chemical plants, nuclear plants, and on ships.

Cost Considerations

Cost for a bus bar system will vary based on numerous factors, such as materials, finish requirements, interconnection scheme and quantity.

In order to achieve the most cost-effective bus bar system, it’s critical to ensure early involvement with your bus bar manufacturer. Early involvement will aid in ease of manufacturing, final product quality, turnaround time and overall cost.