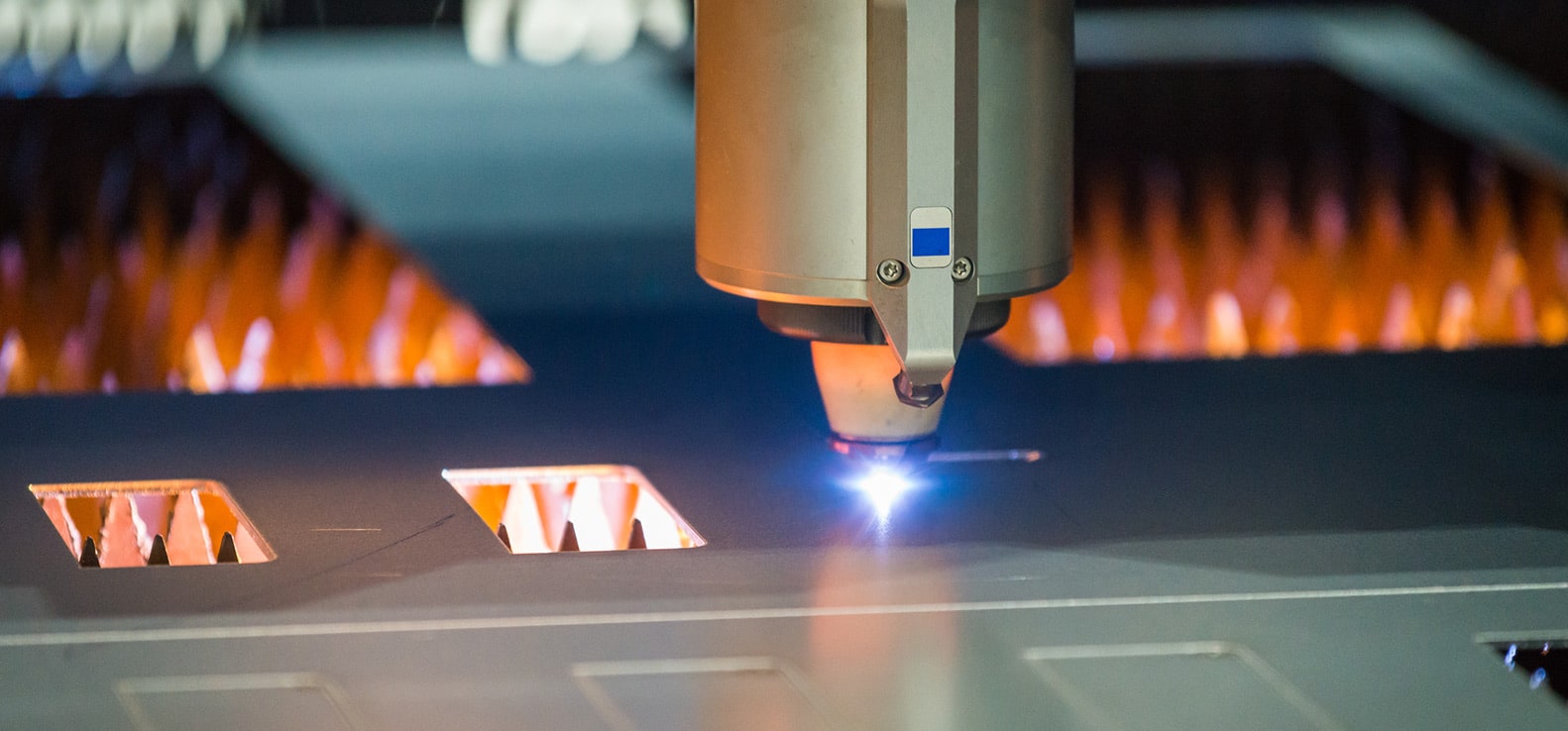

Bus Bar Fiber Laser Cutting

Powerful Fiber Laser Cutting Technology Raises Bus Bar Manufacturing Expectations

EMS Industrial & Service Company is excited to announce our acquisition of 2 state-of-the-art Fiber Lasers. We partnered with the industry-leading Fiber Laser company in order to harness this powerful technology and bring it in-house as part of our bus bar service offerings.

The Fiber Laser uses a Fiber Optics generator to produce a beam of light. This light beam cuts bus bar extremely quickly & accurately. With cutting speeds up to 2,000 ipm and positioning speed up to 6,700 ipm, the Fiber Laser can process material incredibly fast.

This technology processes a wide variety of ferrous & non-ferrous metals to meet and exceed your bus bar needs.

The Fiber Laser is just one component that sets EMS Industrial apart from the competition and distinguishes us as the industry-leading bus bar manufacturer.

Fiber Laser Advantages:

- High cutting speeds in thin sheet metal, including copper and aluminum

- Process ferrous and non-ferrous metals

- Multi kW high efficiency fiber laser source for dynamic processing

- Maintenance free laser source…..means more up-time processing of material

- Integrated shuttle table system for “lights out” processing

- 5’ x 10’ table to allow for maximum productivity

- Allows processing of thicker material

Maximum Thicknesses:

- 3/4” for Aluminum

- 3/4” for Copper and Brass